01

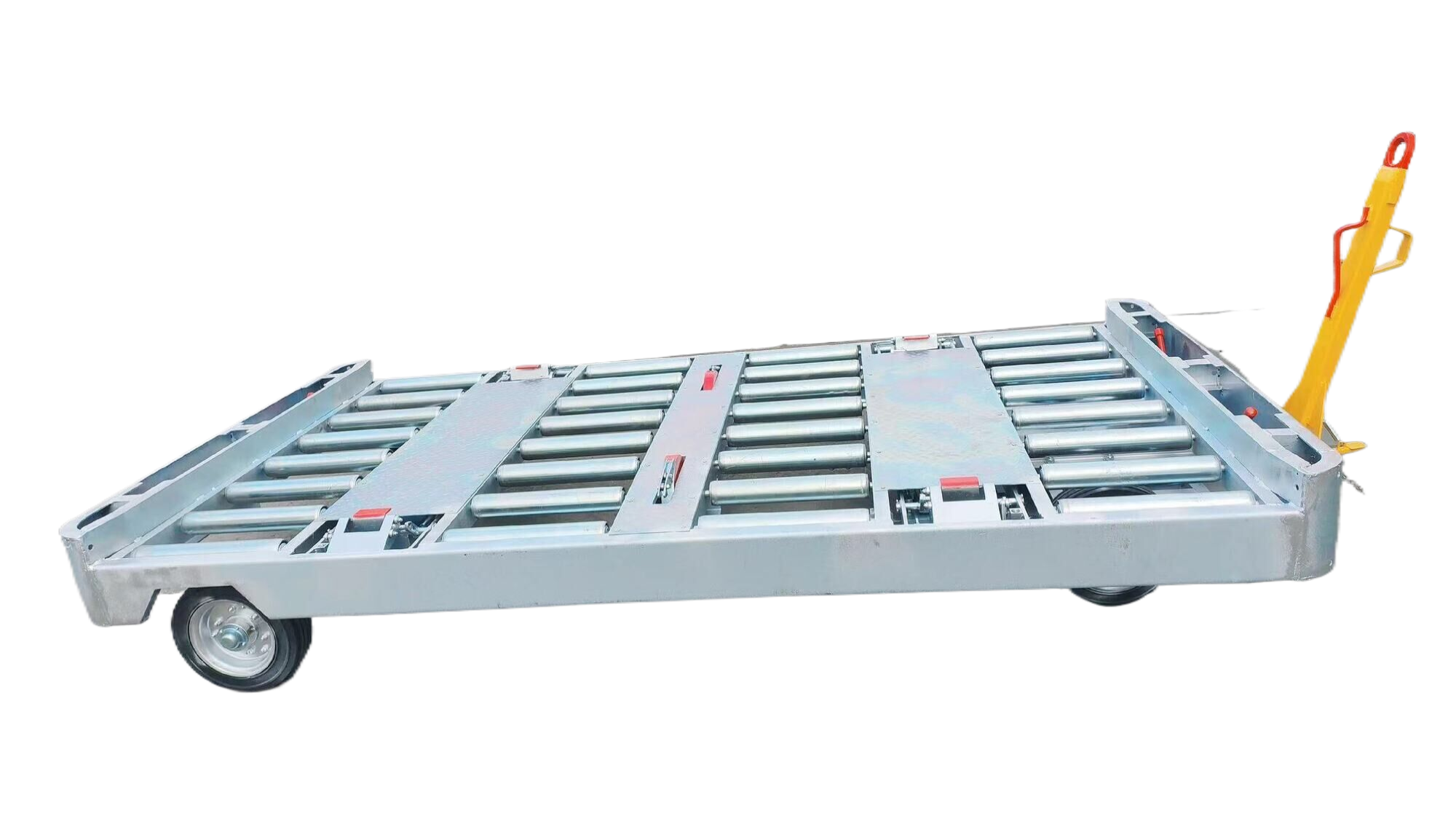

Baggage Cart

ParameterCHIDGE

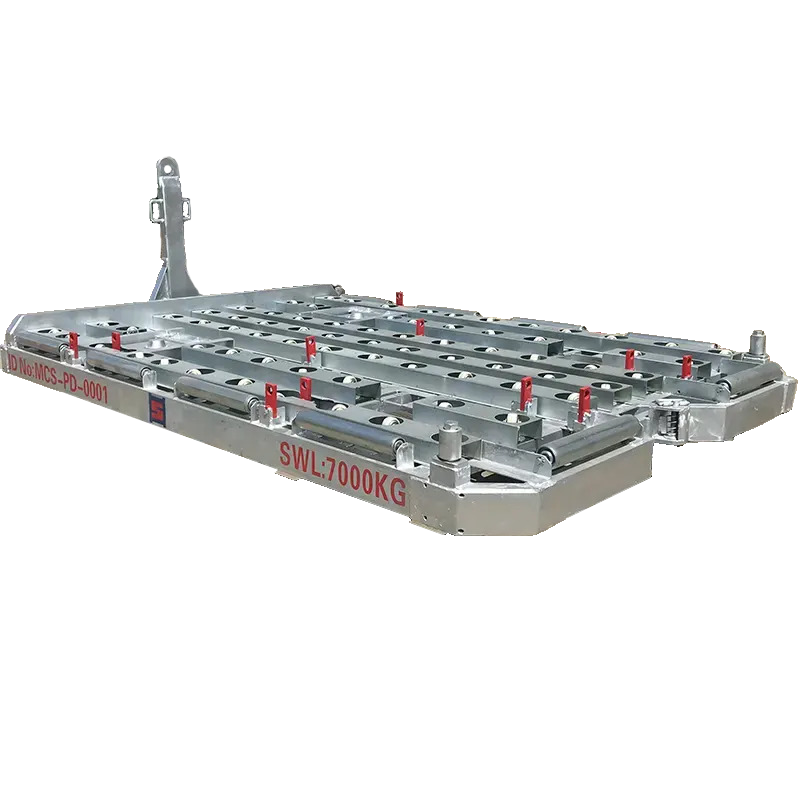

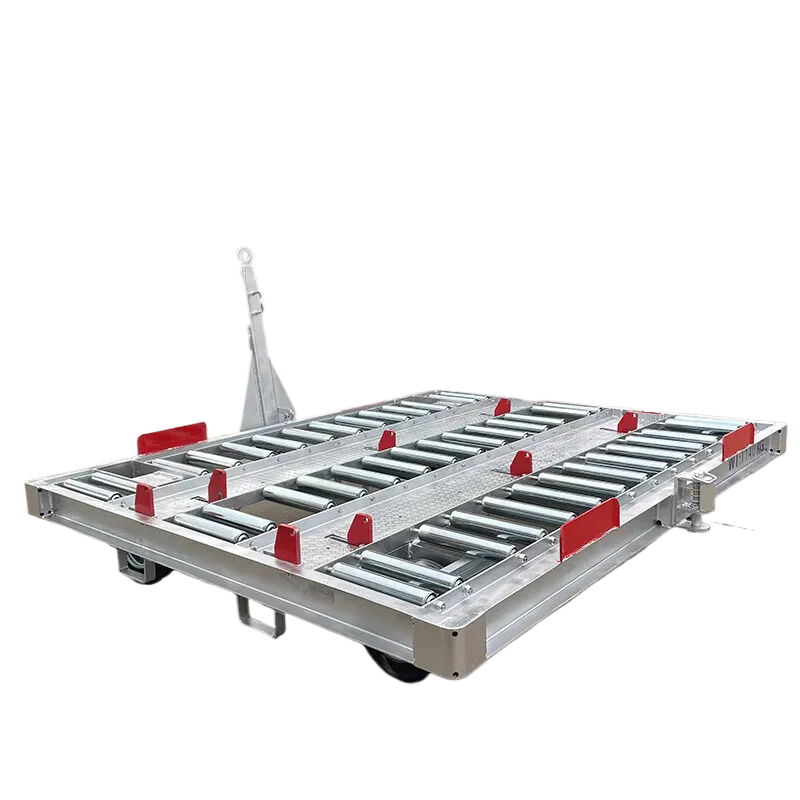

| Product: Four rails baggage cart | |

| Parameter | Material |

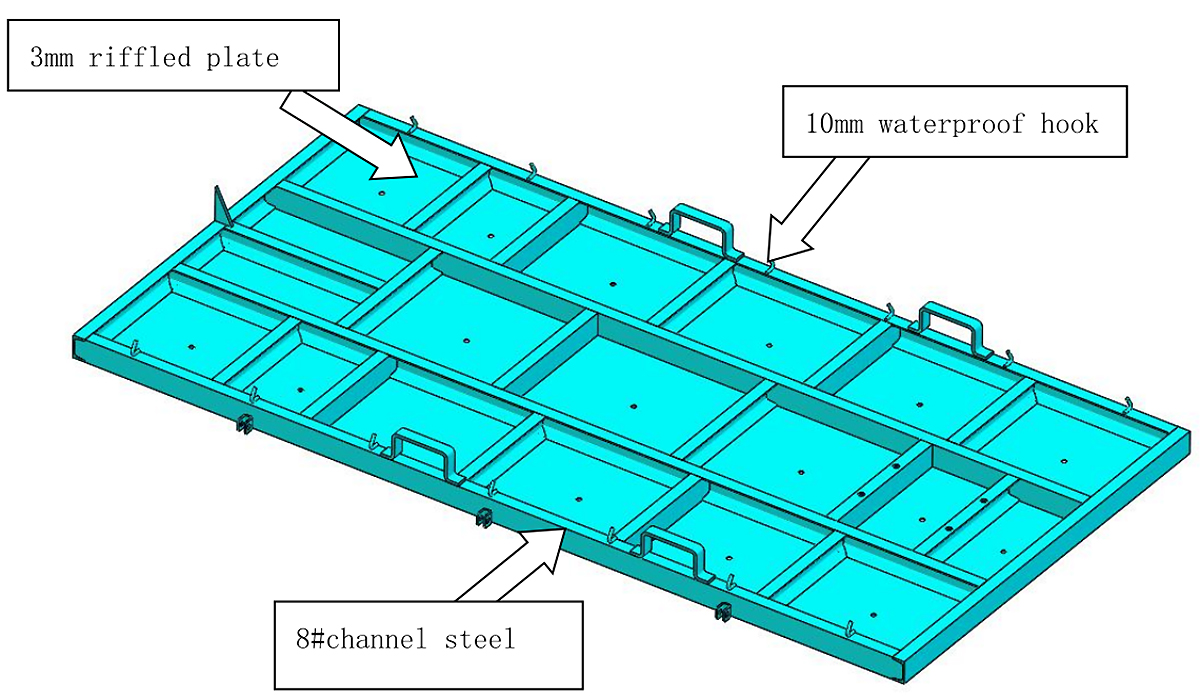

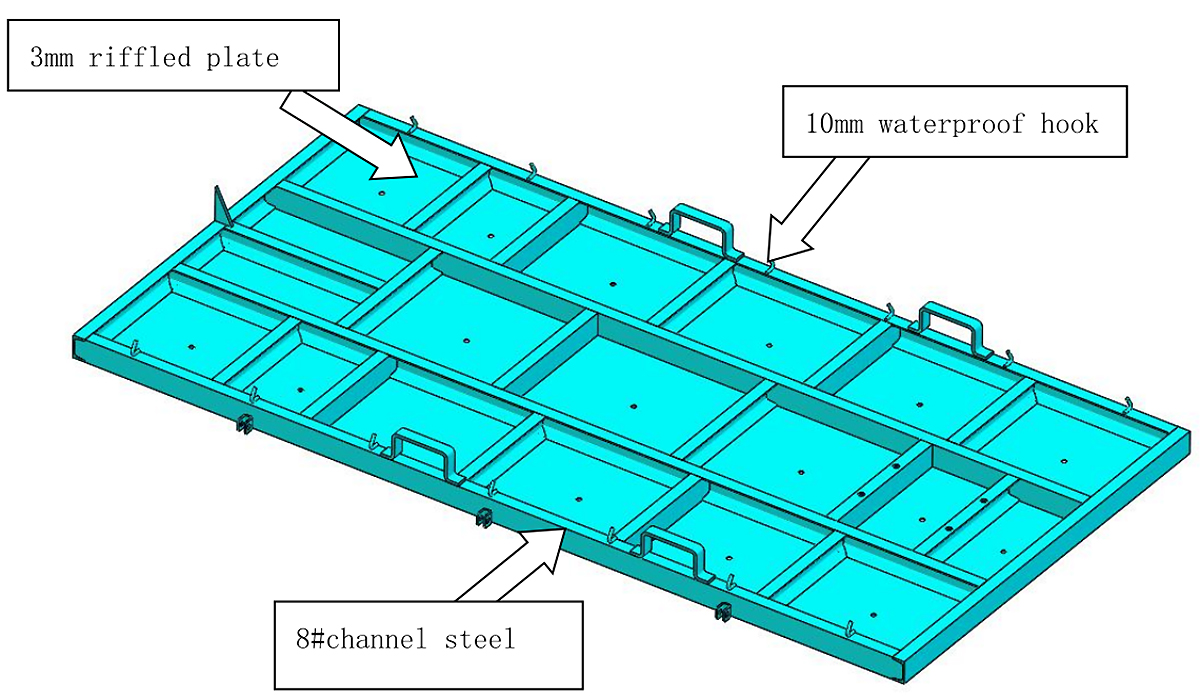

| Size: 4247×1500×1360mm | Body frame: 8 # national standard channel steel and 3 mm thick pattern steel plate |

| Platform size: 3000×1500×560mm | Tire: 16*5-9 solid rubber tire |

| Platform height: 560mm | Drawbar: Φ42×5mm seamless steel pipe |

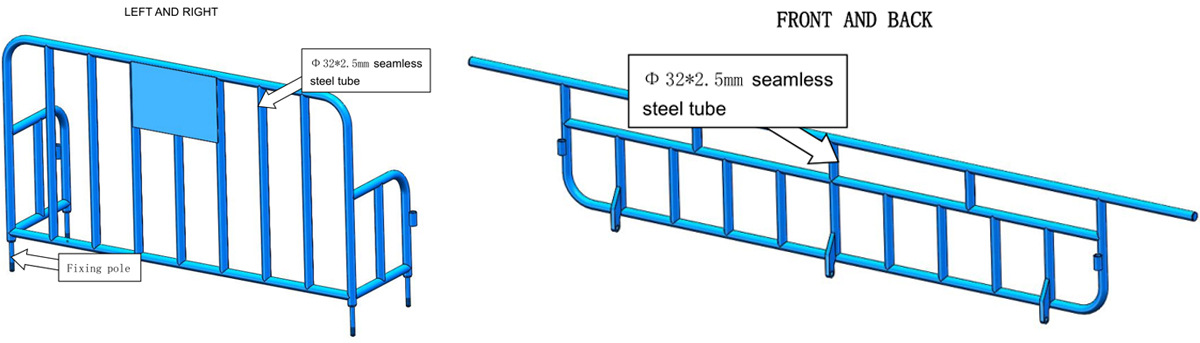

| Speed: 25km/h | Fence: Φ32×2.5mm seamless steel pipe |

| Loading weight: 3000kg | Front and rear axles: Φ76×5mm seamless steel pipe |

| Weight: 550kg | Hook: 20mm steel plate; PinΦ35mm Round steel |

Technical characteristics of productsCHIDGE

1. It is suitable for loading large quantities of baggage, parcels and other bulk goods. It can be moved conveniently in any occasion to meet the needs of operation in various locations. It is suitable for any type of baggage conveyor.

2. The truck can work all-weather and has good performance of rain proof, moisture proof and corrosion protection. Beautiful appearance, reasonable structure, high reliability, convenient maintenance and long service life.

3. The main frame of the trailer is welded with 8 # channel steel and 3 mm pattern steel plate. The welding is full welded and durable.

4. The tire is made of 16*5-9 solid rubber tire, and the rubber is imported with long service life.

5. The front axle adopts a special turntable, which can turn 360 degrees. The structure is reasonable, the center of gravity is safe and stable, and it is durable.

6. The mop has dual functions of multi-vehicle connection and braking. The mop can brake when it falls automatically by gravity.

7. The brake mode is external brake. When the trailer mop is decoupled, the brake system can automatically brake by friction between the brake pad and the tire.

8. The tail is equipped with a spinning spring hook, which is safe and reliable in design, ensures that the bolt is strong and durable, and does not decouple during driving.

9. The tail is equipped with a spinning spring hook, which is safe and reliable in design, ensures that the bolt is strong and durable, and does not decouple during driving.

10. The tail is equipped with a spinning spring hook, which is safe and reliable in design, ensures that the bolt is strong and durable, and does not decouple during driving.

Main parts materialCHIDGE

➢ Frame: L×W×H(3000×1500×560mm)Without drawbar and tail hook

1. The frame is made of 8# national standard channel steel produced by Ma Steel. The dimensions of each rectangular frame of the frame are controlled within 500 *400 mm, and the opening of the channel steel around the frame is inward. The dimensions of the working table (length *width): 3000 *1500mm, and the height of the working table from the ground is 560 mm.

2. The weight of the vehicle is about 550 kg; the maximum load is 3000 kg; the maximum speed of the vehicle is 25 km/h.

3. The workbench panel is laid with 3 mm thick pattern steel plate, which will not rust. There are 3 rows of 16 mm drainage holes drilled on the panel, which is not easy to accumulate water.

4. Install a 10 mm diameter rain cloth hook on both sides of the chassis, opening inward, to prevent scratching of the rain cloth or being scratched or knocked off; and effectively prevent the net cover from falling off.

5. The length of each welding point between the steel plate and the frame of the working table is 150 mm and the distance is 100 mm.

1. The workbench is surrounded by fences. The fence frame is welded by 32*2.5mm seamless steel tube

2. The front and rear fences are fixed, and the height of the fence is 800 mm. The bottom of the fence is welded with a fixed rod through the frame channel steel to increase the strength.

3. The left and right fences are reversible with a height of 465 mm.

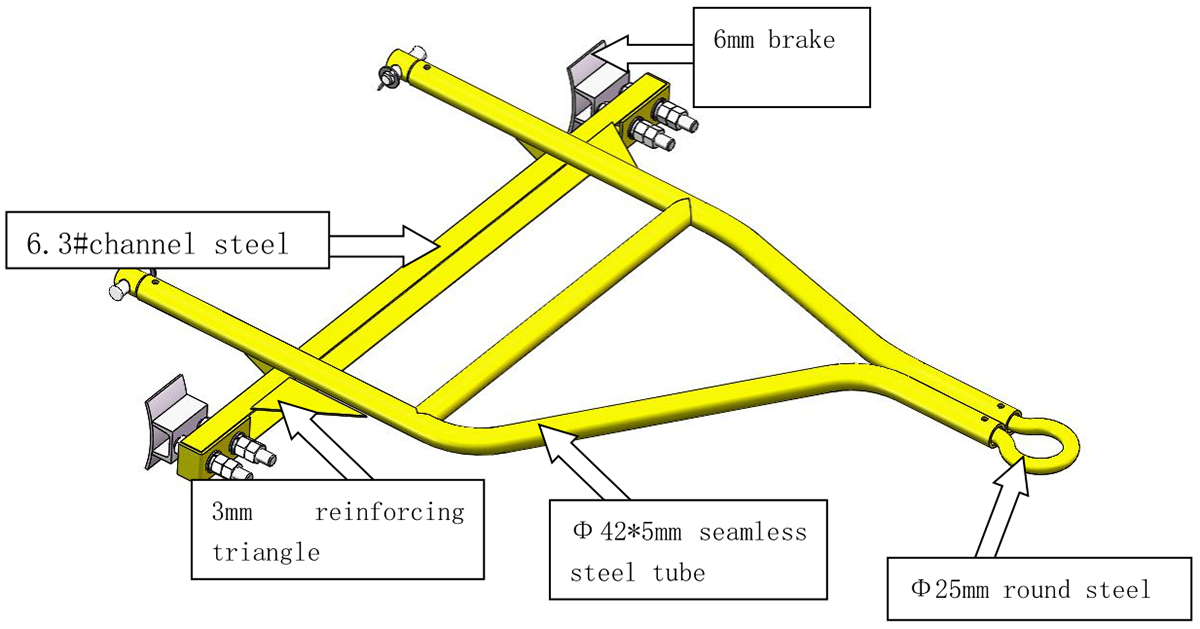

1. The total length of the drawbar is1400 mm and width is 800 mm. The distance from the outermost part of the mop ring to the front end of the worktable is 1100 mm.

2. The distance between the opening position and the end of the connection between the end of the drawbar and the front axle is 25 mm and the aperture diameter is 21 mm.

3. The drawbar is made of 42*5mm seamless steel pipe. The pulling ring of the mop head is bended with 25 round steel. The mop head is inserted into the seamless steel pipe part for 70mm, the insertion part is fully welded with pins, and the inner diameter of the drawbar diameter is 75mm.

4. The height difference between the middle line of the drawbar head and the middle line of the drawbar tail is 220 mm.

5. When the drawbar is lowered, the vehicle brakes automatically. Under the braking condition, the height of the mop head off the ground is 70-150 mm.

6. The length of the brake bar is the same as the front wheel spacing. It is made of 6.3 # channel steel.

7. The brake part is made of steel plate with convex arc surface. The thickness of steel plate is 6 mm and the length is 170 mm.

8. The triangular plate with 3 mm thickness is used to reinforce the elbow of the drawbar and the brake bar to ensure the strength.

9. The brake shall be of two-wheel adjustable type. The adjustable brake shall be of single nut on the inside and double nuts on the outside. Spring gaskets shall be installed at all nuts.

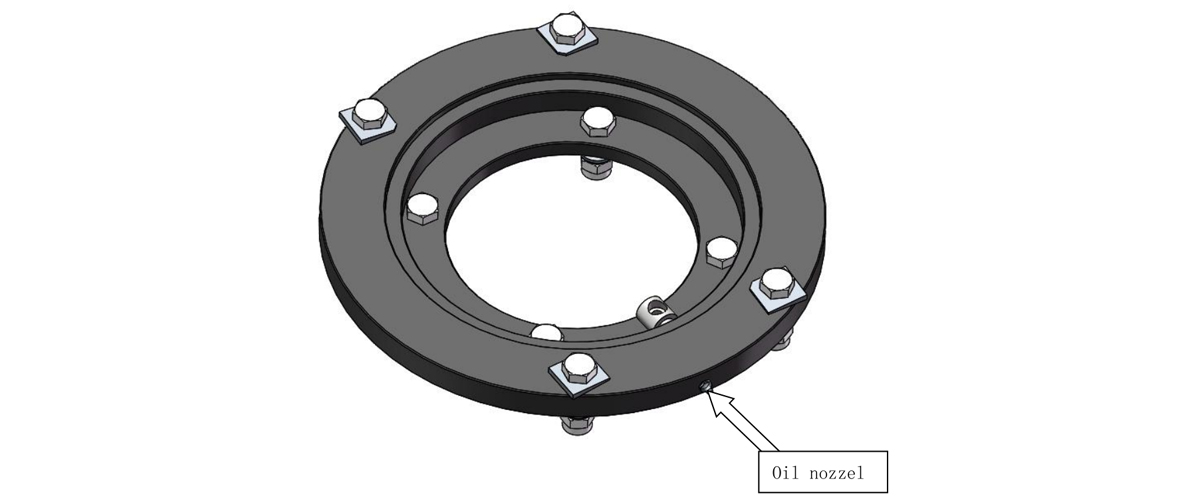

1. The outer diameter of the outer disc is 400 mm, the inner diameter of the outer disc is 270 mm, the thickness is 35 mm, the outer diameter of the inner disc is 320 mm, the inner diameter of the inner disc is 200 mm, the inner diameter of the inner disc is 62 steel balls with a turning angle of 360 degrees

2. The outer disc and the inner disc have four screw holes with an aperture of 18 mm. The diagonal angle of the four holes is 120 degrees. The edge of the hole on the outer disc is 10 mm from the outer edge of the outer disc and the edge of the hole on the inner disc is 10 mm from the inner edge of the inner disc.

3. The turntable is equipped with butter nozzle to facilitate the filling of lubricating oil.

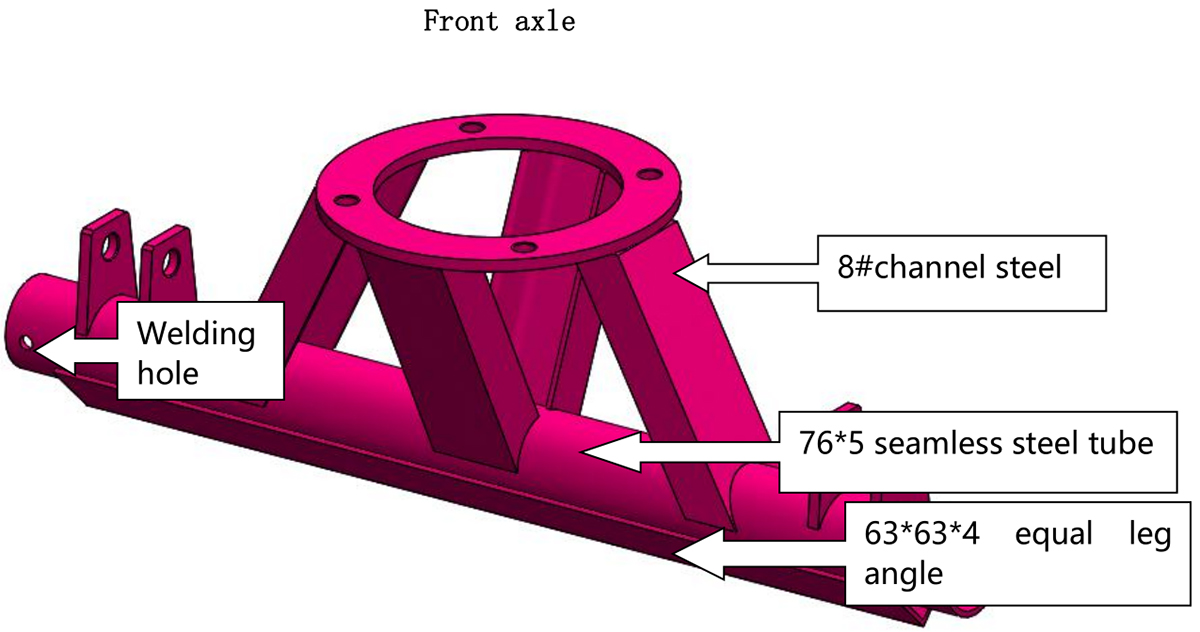

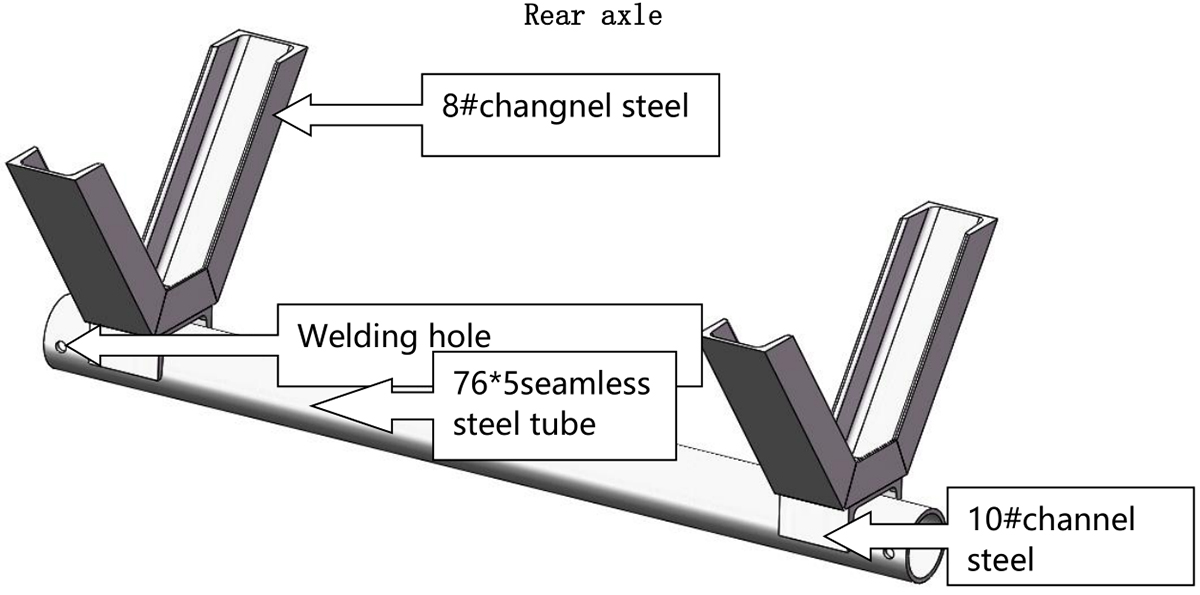

1. The front and rear axles are made of seamless steel tubes with a diameter of 76mm and a wall thickness of 5mm.

2. The front axle and the turntable are fully welded with four 8 # national standard channel steels, which are connected by lantern frame. The strength of the front axle is strengthened by adding 63 * 63 * 4 equal angle steels under the front axle

3. The connection between rear axle and frame is welded by 8 # national standard channel steel and 10 # national standard channel steel.

4. The front wheel spacing is 1100 mm, the rear wheel spacing is 1200 mm, and the front and rear wheel spacing is 1900 mm.

5. The connection between the front and rear axle heads and seamless steel pipes is made by perforated bolts and full welding.

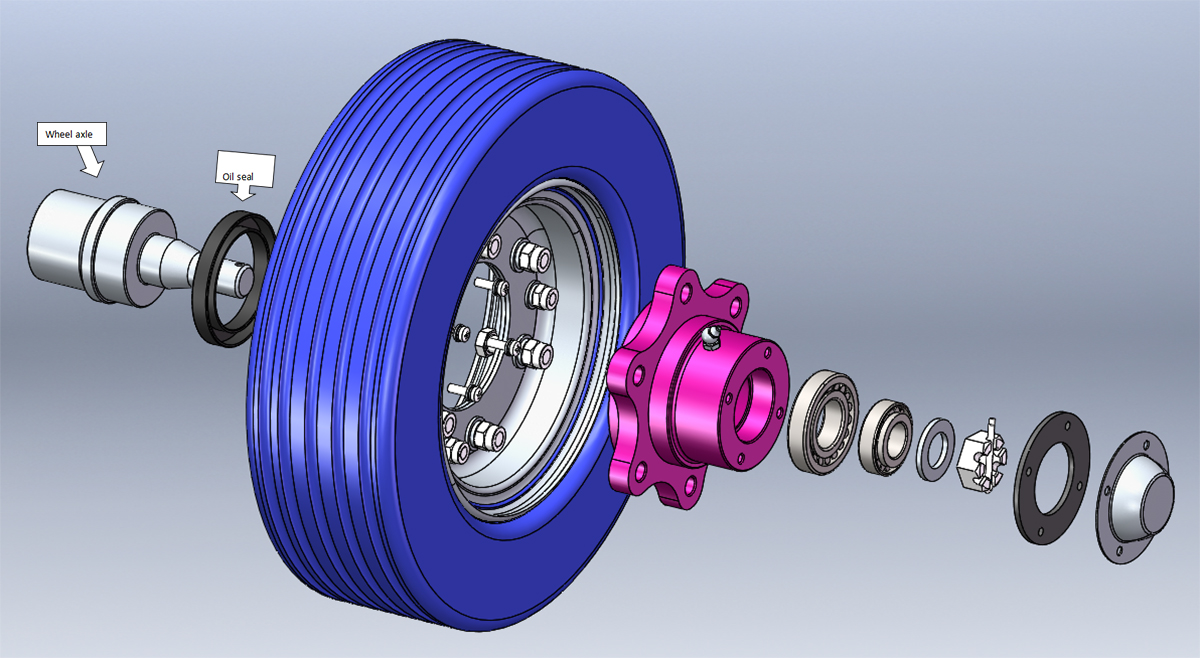

1. The diameter of hub is 290mm, the diameter of middle flange seat hole is 100mm, the steel ring fastening screw is 10mm, and the tire screw hole is 14mm. The tire is made of 16*5-9 solid rubber tire produced by Shanghai Jiuda Rubber and Plastic Company. The tire is made of imported rubber, which is more wearable in use.

2. The bearings are imported NSK with models of 3007 and 30205. Butter nozzles are added to the hub to facilitate lubrication. Great Wall brand is used as lubricating grease, and the temperature of lubricating grease is - 20 - 120 C.

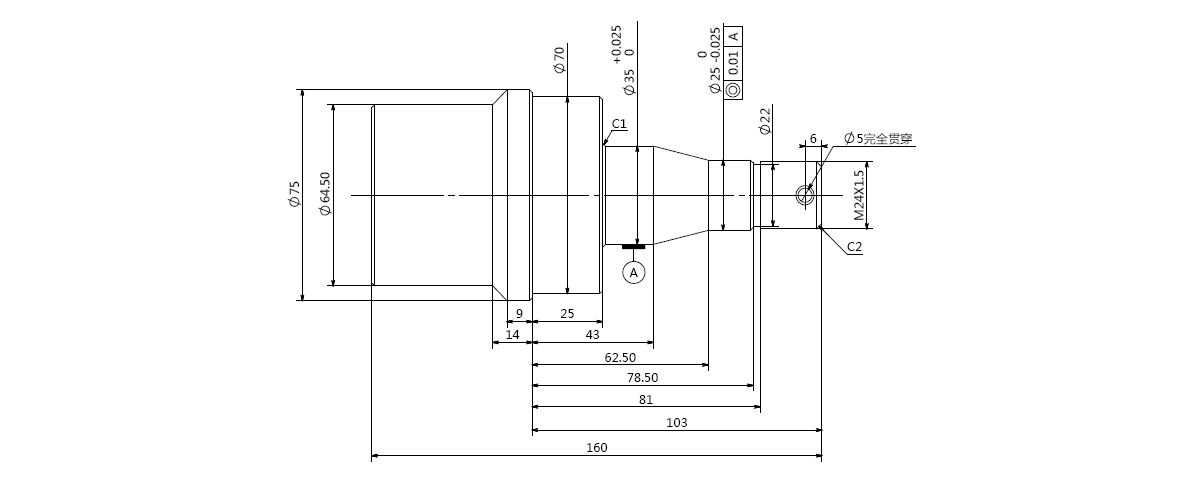

3. In order to prevent the occurrence of flywheel caused by various reasons in the operation of tyres, our company specially installs self-made flywheel gasket on the outer side of bearings. The size of the gasket is 1 mm smaller than the outer shell of bearings, which can effectively prevent the direct flywheel from being damaged by bearings and is more secure in safety. At the same time, the gasket can prevent the oil spillover and keep grease lubrication all The tyre axle head is processed by 45 # steel after quenching and tempering. The dimension of 30207 bearing must be clearance fit for easy installation. The dimension of 30205 bearing must be interference fit for strengthening strength. At the same time, the strength of axle head must be chamfered at the bearing fit.

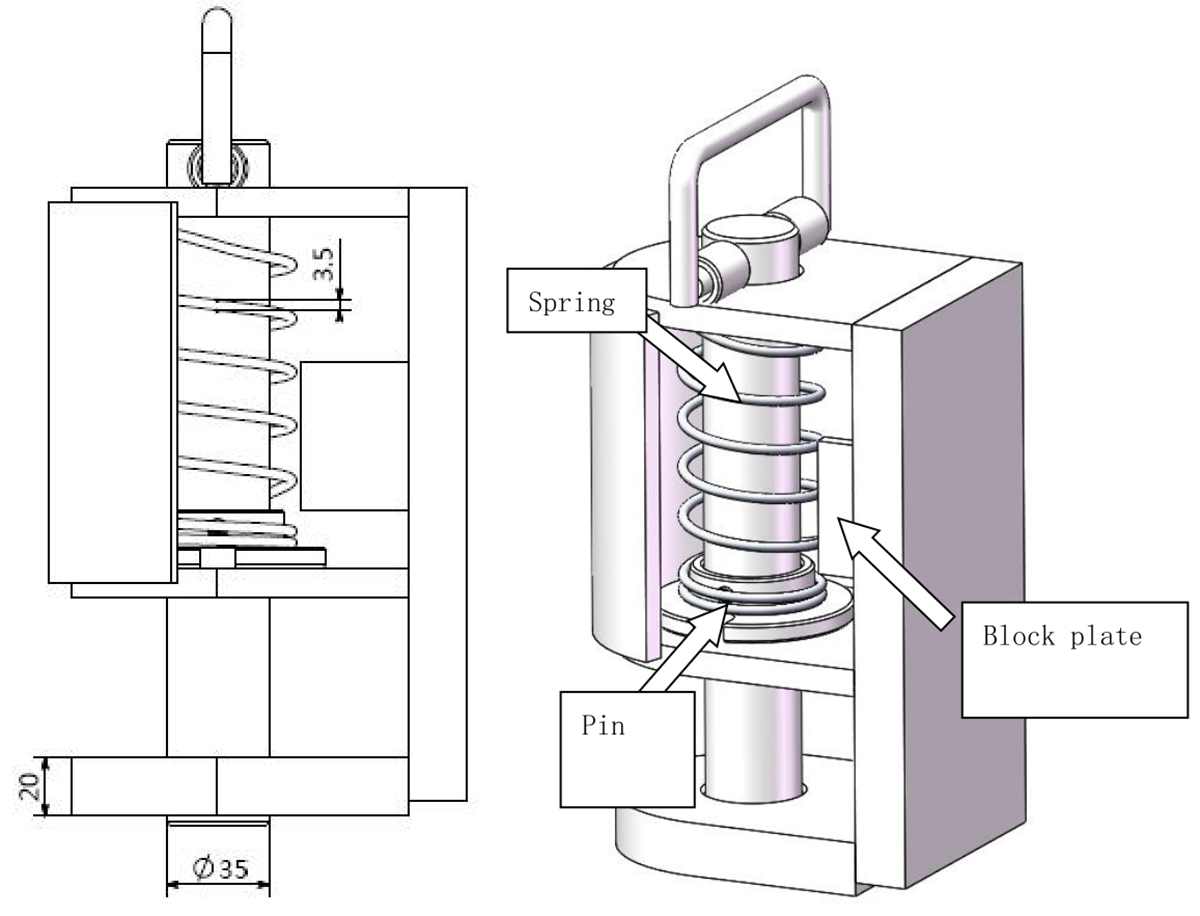

1. The hook is made of spinning spring hook. The handle of the hook is made of 45#steel with an outer diameter of 35mm. The round steel is tempered and galvanized. The bottom of the hook is made of 20mm steel plate to ensure high strength.

2. The hook handle is fixed by a double elastic cylindrical pin structure, which ensures strength and safety, makes maintenance more convenient and saves cost

3. Spring design is adopted. The diameter of the spring is 3.5mm, and the pre-pressure of the spring is set in advance. The multi-structure ensures that the tail hook pin will not jump out.

4. With the unique anti-skip baffle design, only when the spring base slot is aligned with the baffle, the tail pin can be lifted to ensure that the tail pin will not skip (as shown in the figure).

The whole vehicle is treated by high pressure shot peening, and two-degree zinc-rich epoxy rust-proof paint is used as primer. The paint has good adhesion and excellent rust-proof ability. The primer is sprayed within 2 hours after drying. The top coat is made of automobile special polyurethane enamel, which can keep the body surface bright and new for a long time. The main connectors such as back bolts and connecting bolts are galvanized. Paint color according to customer requirements.

Products

Products