01

CD-T150 aircraft tow tractor technical specification

Product StandardCHIDGE

➢ IATA AHM 905 Civil Airport Support Equipment Reference.

➢ IATA AHM 910 Airport Ground Support Equipment Basic Requirement.

➢ IATA AHM 913 Airport Ground Support Equipment Basic Safety Requirement.

➢ IATA AHM 915 Standard Control.

➢ MH/T6017-1999 Aircraft Towing Tractor.

Main Technical ParametersCHIDGE

| Max. Traction Value | 120KN |

| Max. Towing capacity | 160T |

| Gross weight | 15T |

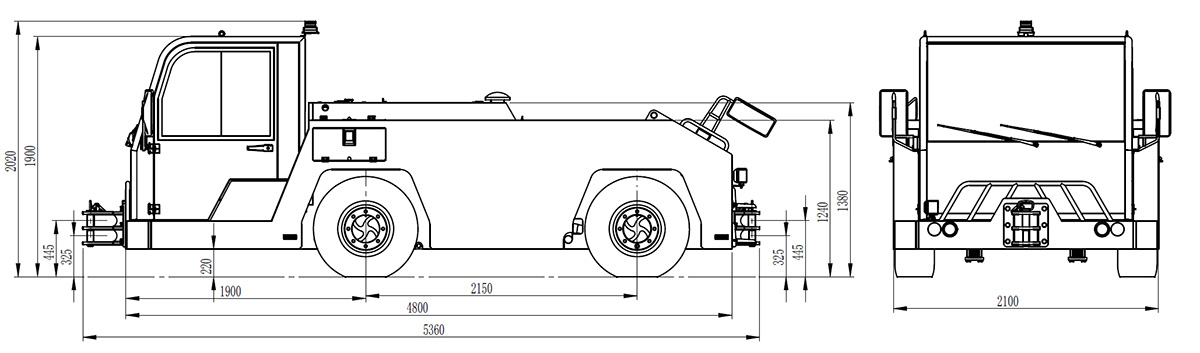

| Overall dimension | |

| Length (without towing assembly) | 4800mm |

| (With towing assembly) | 5360mm |

| Width (with rear view mirror) | 2100mm |

| Height | 2020mm |

| Wheelbase | 2150mm |

| Ground Clearance | 200mm |

| Turning Radius | 5800mm (two wheel) , 3400mm (four wheel) |

| Max. Vehicle Speed | 25 Km/h |

| Drive method | hydraulically mechanical transmission, double axle four-wheel driving. |

| Braking | hydraulically, two-way, accumulator pressure maintaining |

Main Structure and ConfigurationCHIDGE

The T150 aircraft tow tractor is made up of commercial chassis, engine, gearbox, transmission shaft, front/rear axle, driver's cabin, braking system, steering system, control system and so on.

Chassis

1. Main Truck Framework

It is completed by welding of the high-strength steel plate with relief annealing on the entire welded body. This is in conjunction with the entire process of the surface and assembling holes. The upside is covered with board and is adhered with antiskid materials.

2. Suspension

Front axle adopts the leaf spring suspension.

3. Towing Hook

There are towing hooks assembled in the front and rear side of the vehicle.

Diesel Engine

The Diesel engine is assembled on the back of the main vehicle framework, which makes it is best distributed for the load of front axle and rear axle.

Design: Deutz BF4M2012-10T3R Diesel Engine

Type: Four Stroke water cooling, straight-spurt type turbo diesel engine.

Cylinder: 4 cylinders

Rated power: 74.9kw / 2300 rpm

Max. Torque: 390Nm / 1400rpm

Fuel system: Tier 3 with ECU pump Fuel consumption: 215 g/ kW·h Emission standard: EU Stage III

Transmission, Front / Rear axle

The gearbox and engine is connected through the transmission shaft which is assembled on the ear seat of the two side of the middle part of the main vehicle framework. The two output ends of the gearbox are connected through the main speed-down of the front/rear transmission shaft and drive axle. The power of the engine passes through gearbox, transmission shaft, main reduction gearbox, differential axle, reducer aside the wheels, wheel rim and at last to the tyres that achieves the complete axles driving.

1. Gearbox

➢ Design: US DANA Gearbox T12000 series

➢ Gears: Forward four / Backward three

➢ Control measurement: Electro-hydraulic power gearing system can achieve the slow starting of 0-4.5Km/h, the gear shifting operation is soft without impact.

2.Transmission Shaft

➢ Made-in-China

3. Front / Rear Drive Axle

Front Drive Axle:

➢ Manufacturer: USA DANA imported origin

➢ Type: planetary geared type / swinging type

➢ Steering system: Hydraulic

➢ Connection method of the vehicle body: Leaf spring suspension

➢ Differential mechanism: Planetary geared type

Rear Drive Axle:

➢ Manufacturer: USA DANA imported origin

➢ Type: planetary geared type / swinging type

➢ Steering system: Hydraulic

➢ Connection method of the vehicle body: Rigid connection

➢ Differential mechanism: Planetary geared type

Tire

➢ Tire model: 300/70R15

➢ Quantity: 4 tires

Steering System

➢ Type: Full hydraulic power steering

➢ Assistant assembly: it is assembled with electric pump that is assembled independently from the engine which can provide the optional turning function.

Electrical System

➢ The equipment has complete electric operation system which is fully electric and conveniently operated.

➢ System voltage: 24VDC

Driver's Cabin

➢ Type: Fixed.

➢ Configuration: Fixed rear window, double door, adjustable seats, device display system, control system, screen wiper, defrosting equipment, left-right back mirror, rear drawbar mirror, yellow alert light on top of the cabin.

Air Condition

In order to make the driving more comfortable, the equipment has the cool/warm air conditioning system.

Beacon Light System

➢ Back light: far / near light, position light, backup light, direction signal light, braking light, braking light, Hitch & pin light.

➢ Front light: far/near light, position light, backup light, turn light, braking light, hitch & pin light

➢ Vehicle ceiling light: Driver's cabin ceiling light, Alert light

Emergency Stop Switch of the Engine

There is an emergency stop button in each driver's cabin. The driver can stop the vehicle if it meets any emergency issue.

Others

In order to provide guidance for customer to use such equipment and provide a good daily maintenance service on the equipment, there will be supplied with the technical documents as well as the special tools and other optional components when the equipment exit the manufacturer's workshop.

Products

Products