01

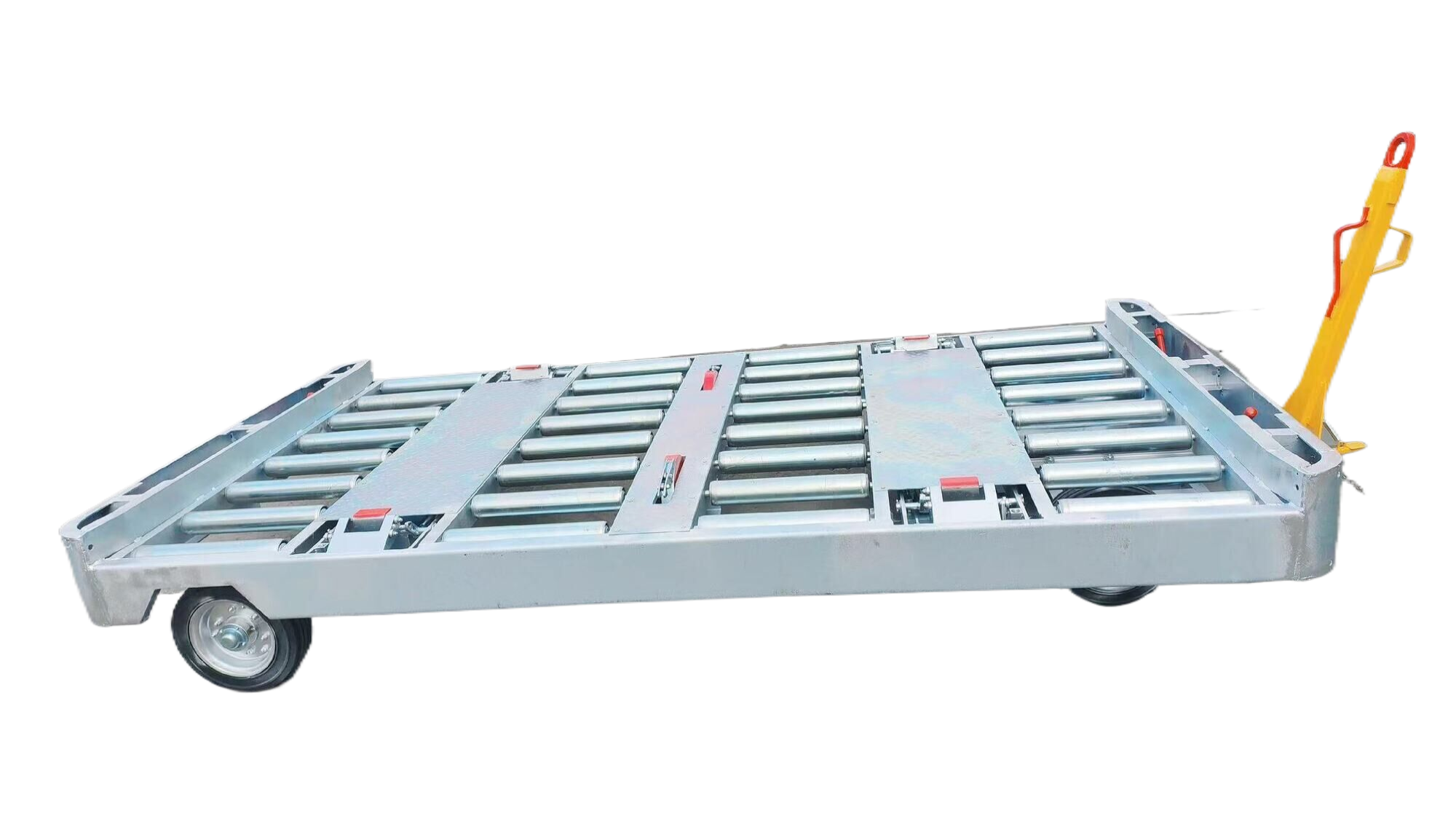

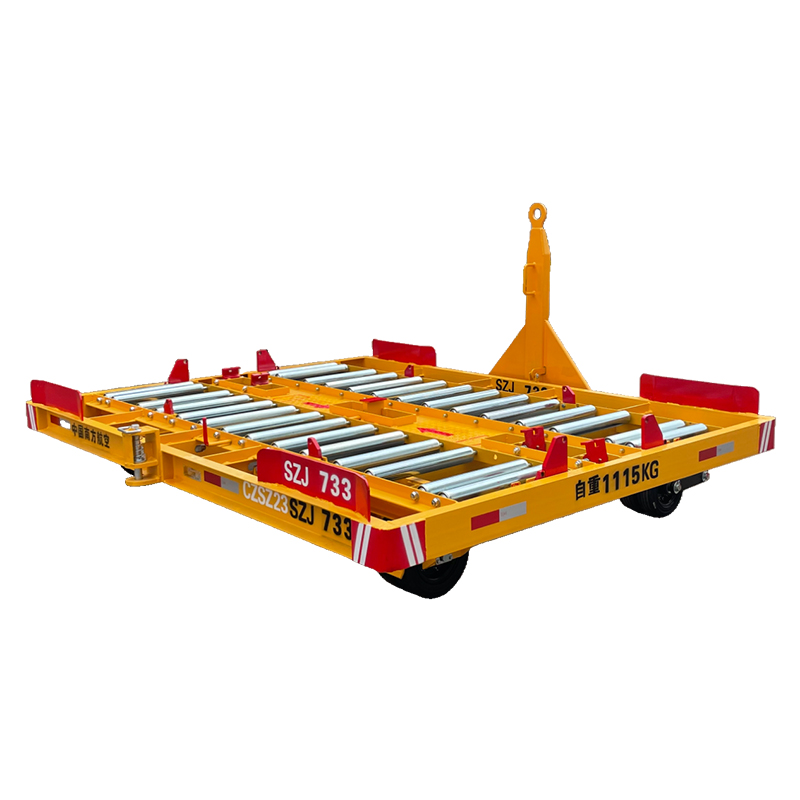

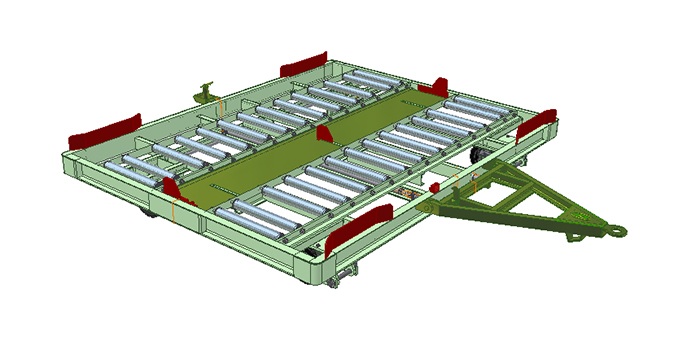

7TPallet dolly

CHARACTERCHIDGE

➢ Solid rubber tyre for longer life

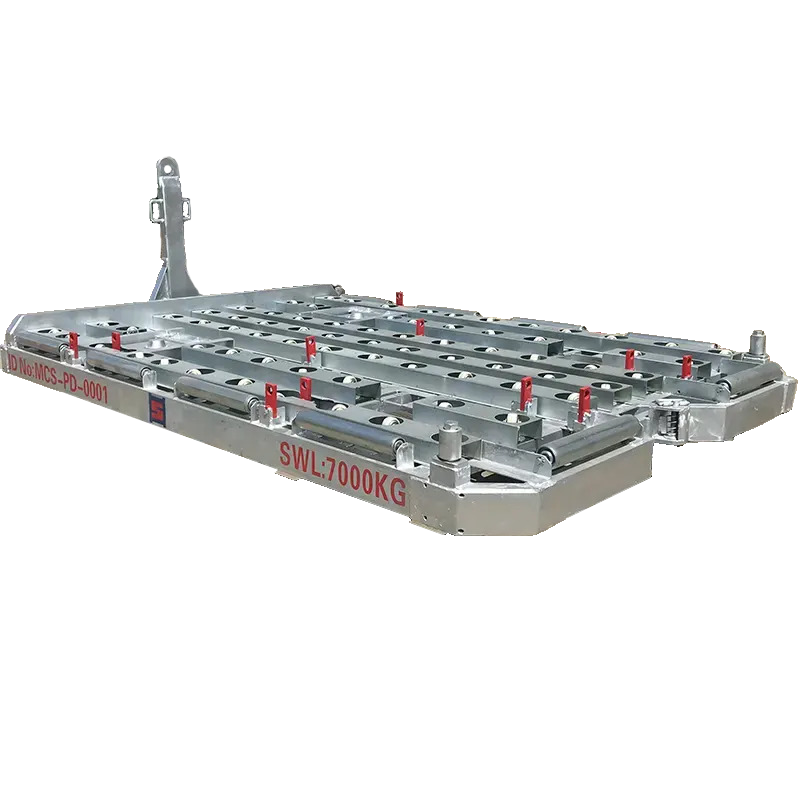

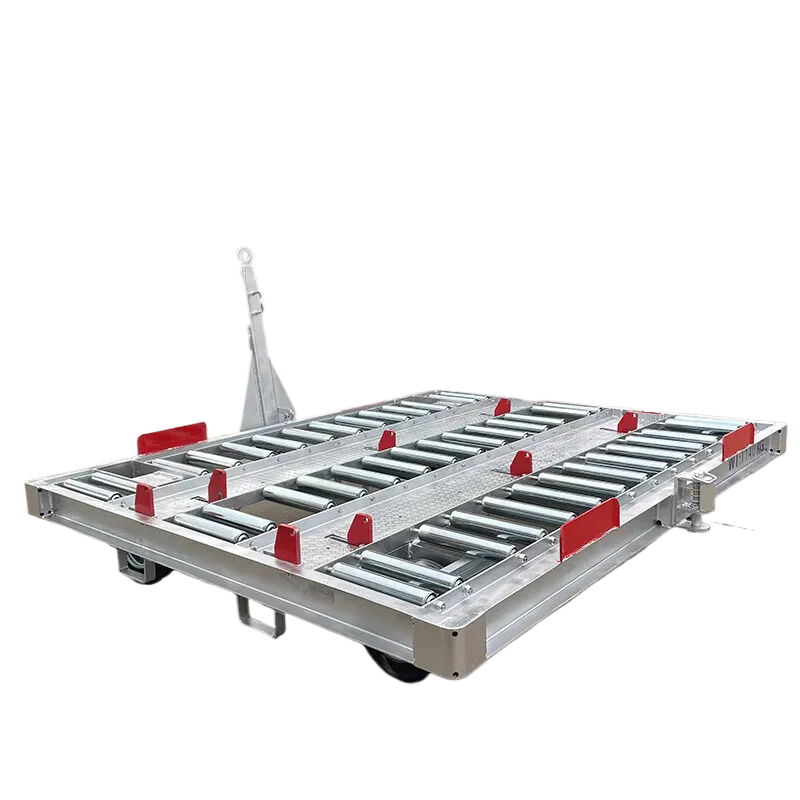

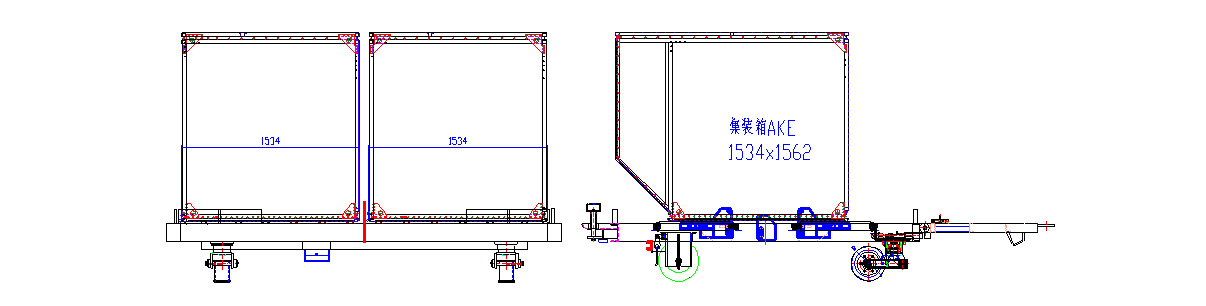

➢ Loading; The trailer according to the pallet and container size, equipped with fixed limited guide plate on the two side, 3sets of movable baffles at the both ends and the middle, The movable baffles at both ends are loaded with fall insurance, The boards can be loaded with.P6P.P1P.PQA pallet, or LD1.2, LD2.2 container.

➢ Four fixed baffles in front and back reinforce the guiding function to prevent the goods from being jammed when the direction of loading is slightly improper.

➢ The tail is equipped with self locking hook device to prevent the rear car from being decoupled so that the train can be smoothly connected.

➢ There are two rows of 28 galvanized roller drives, with a decorative walkway in the middle for easy operation.

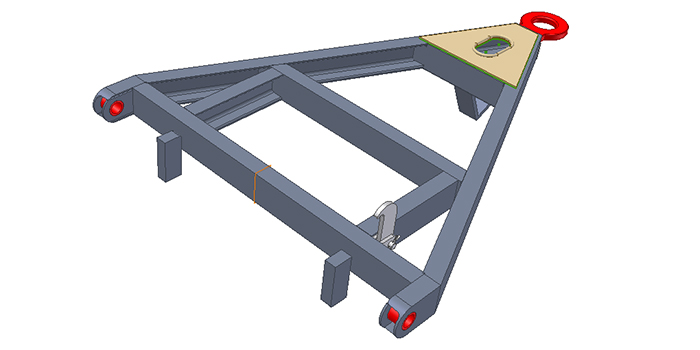

➢ The mop has dual functions of multi vehicle connection and brake.

➢ Design the right and left fork parking spaces to facilitate the use of forklift truck towing card.

Technical parameterCHIDGE

| Size (L*W*H mm) | 4135×3400×625 |

| Platform (L*W*H mm) | 3400×2660×508-518 |

| Weight | ≥1050Kg |

| Loading weight | 7000Kg |

| Turning Angle | ≥25 |

| Mix turning radius | ≤4500mm |

| Max speed | 25km/h |

| Wheel base | 1850mm |

| Tread | 2478mm |

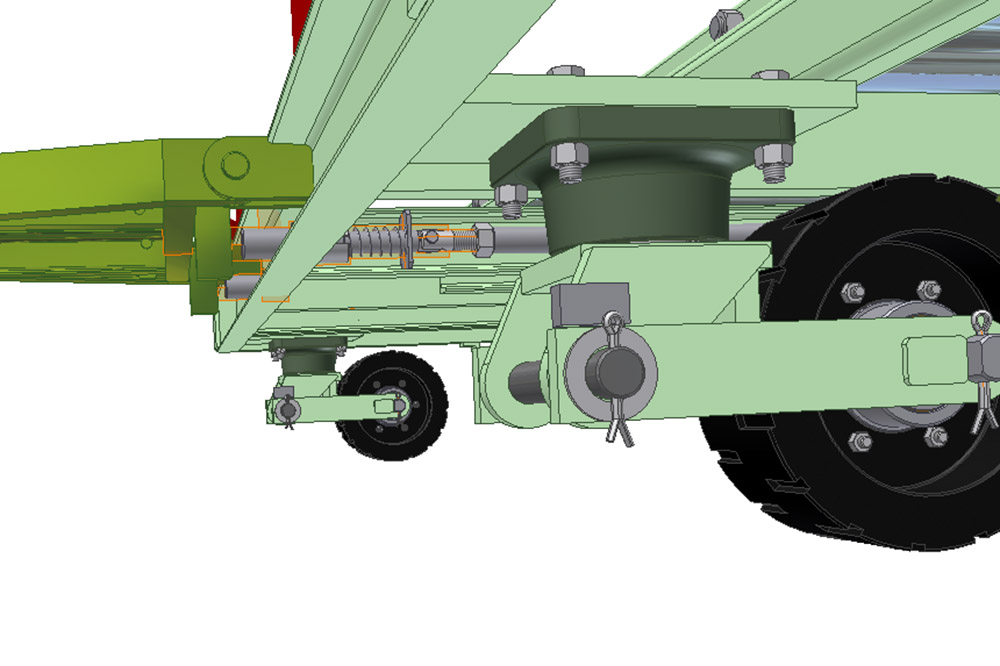

Frame

Adopt national standard 16 #, 10 # channel steel, four corners of the steel plate wrapped into a circular angle, roller beam using 63 # x8mm thick angle iron, middle with a walkway, sealed with 3mm pattern steel plate, easy to operate.

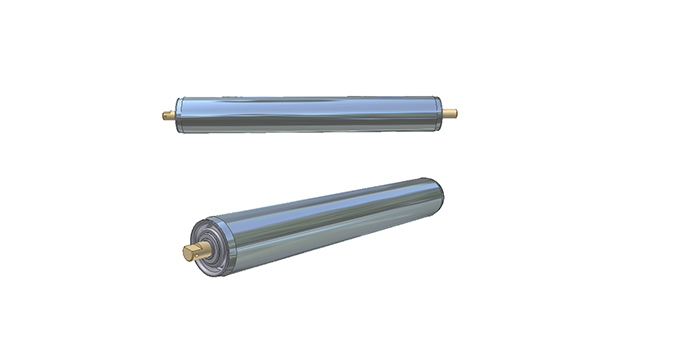

Roller

The working face adopts 28 rows of rollers, and the rolling rod is 76mmx4mm seamless steel pipe with galvanized surface. The roller rod is designed as a built-in bearing with both ends closed. The two ends of the roller rod are fixed by M20 self-locking nuts. The roller rod has the greatest advantages of non-shedding, impact resistance, dust proof and not easy to be damaged.

Drawbar

Adopt 8# channel steel whole welding, the mop has brake function, when the operation produces decoupling, the mop drops down by self-weight to withstand the brake rod brake rear wheel. The mop design has a regulating function, generally adjusting to the mop head height from 150-200 mm to the rear wheel.

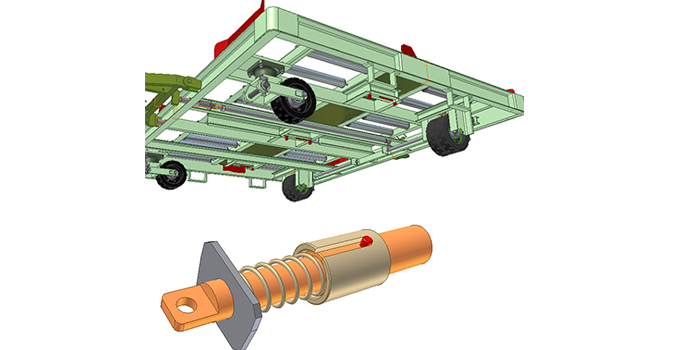

Brake

Designed as a double brake, the main solution to two groups of rear wheel wear (including a single group of new wheels) can be adjusted separately each group, so that the tire and brake plate more consistent, to avoid the danger of self-braking vehicle rotation, so that the brake more safe and effective.

Front wheel

The universal front wheel is designed with 360 degree steering function, flexible steering and 300-120 wheel solid wheels.

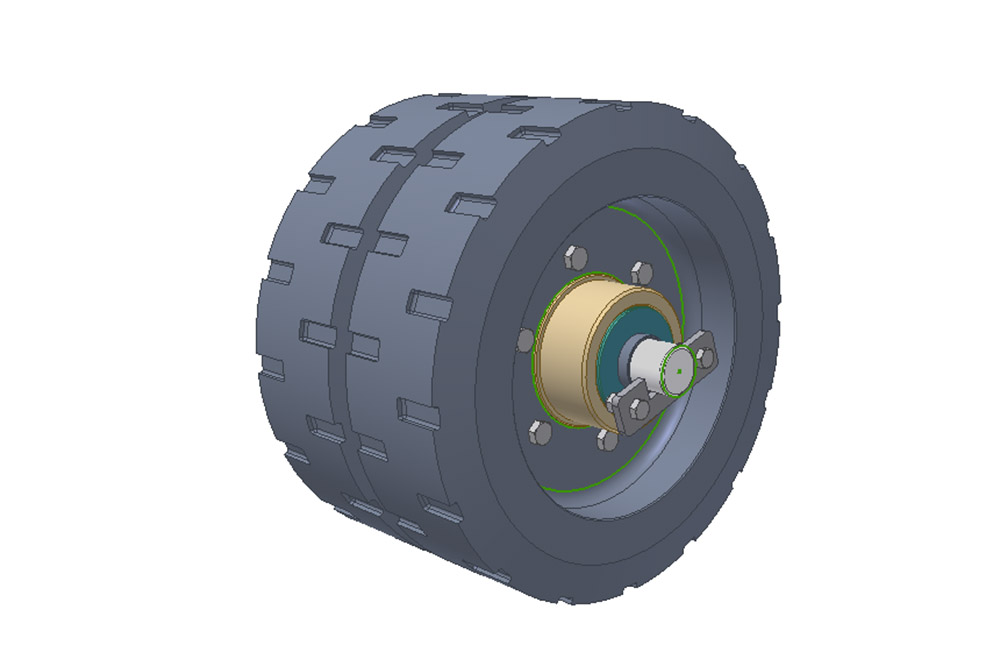

Rear wheel

The rear wheels are 2 sets of fixed wheels (two wheels). All solid core rubber wheels are adopted, with a specification of 350 * 100.

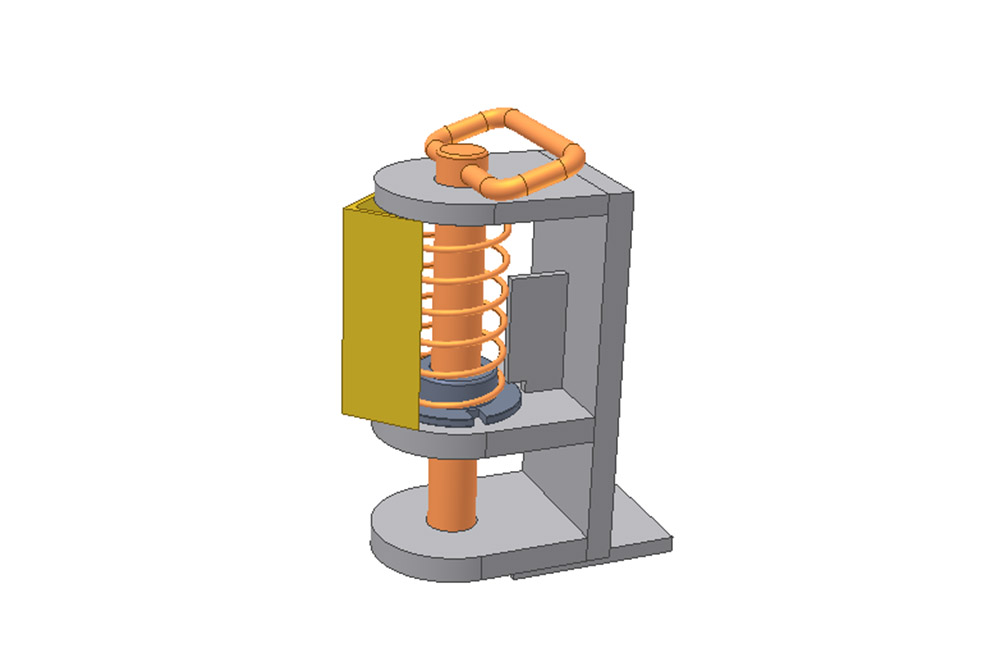

Rear hook

The rear is equipped with inner spring safety device, so that the train can be safely connected and not easy to unhook.

Surface treatment

Use the most effective automatic rotating closed shot blasting machine to remove rust, and then use high-grade anti-rust topcoat anti-rust, the last two times high-grade polyurethane topcoat.

LoadingCHIDGE

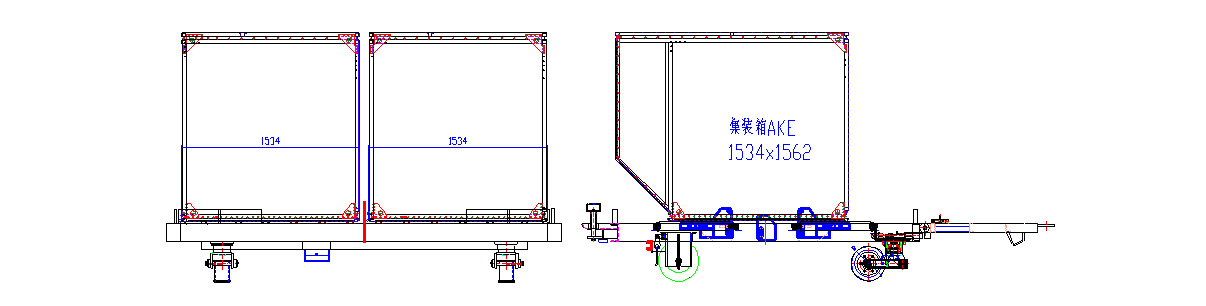

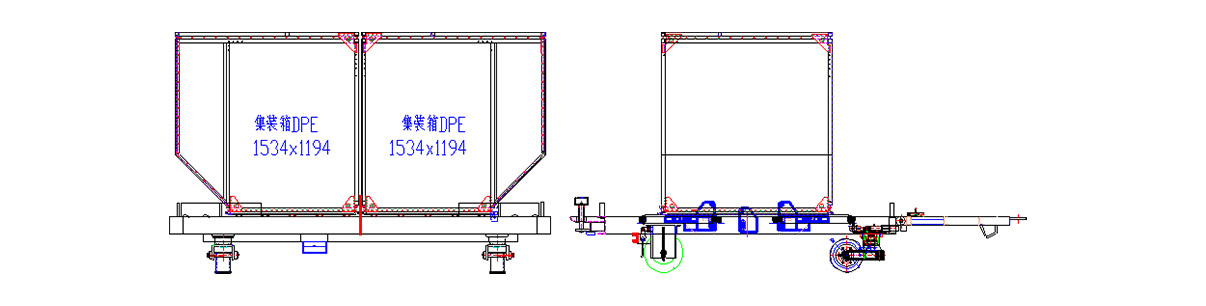

➢ Loading 2pcs LD1 container

Products

Products